Switch cabinet supporting

One.Overview

The front end of the system adopts the wireless temperature measuring terminal, and the temperature measuring terminal can be conveniently installed on the contact point of the high-voltage charged body to accurately track the temperature change of the hot contact. Using the rf technology to transmit temperature information, the collector and the collection point are realized, which is safe and reliable. This system wireless convergence in the terminal can receive 1024 wireless temperature measurement data of terminals, accurate reports in the operation of all high voltage equipment easy fever parts being measured temperature rise, provide reliable data basis for equipment safe operation, and provide scientific basis for the state of the equipment maintenance; Installed in the monitoring center temperature monitoring software, powerful system database through the man-machine interface to the geographical distribution, junction temperature, operation parameters, forecast alarm information, historical parameters by graphics, tables, such as curve, stick figure, such as forms of visual display, provide the most direct and reliable data basis for policy makers, eliminate hidden dangers and minimize accidents.

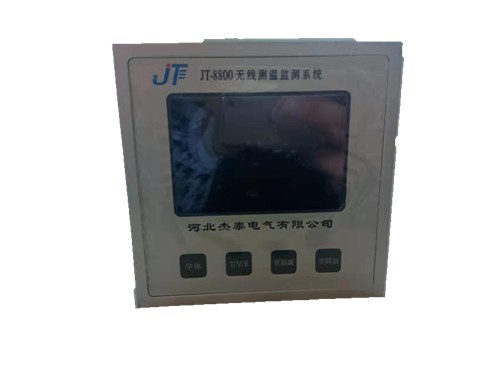

Two.System composition

The system consists of wireless temperature measuring terminal, wireless repeater, wireless convergence terminal and background monitoring system.

Three. Technical parameters

1. Frequency range: 433MHz-434.79MHz (no application);

2. Transmission distance: 800m (no obstruction);

3. Output power: +30dbm;

4. Receiving sensitivity: -123dbm;

5. Comply with the requirements of low temperature GB/T2423.1 and high temperature GB/T2423.2, suitable for use in areas with poor weather conditions;

6. Waterproof level: not waterproof, suitable for indoor;

7. Display mode: independent LCD display;

8. Interface mode: RS232, RS485;

9. Interface mode: RJ45 Ethernet interface (optional);

10. Power supply: direct current flow 110V to 240V;

11. Dimensions: 483mm x height 45mm x depth 160mm, height 1U.

Four.Technical indicators1. Accuracy of system data: the accuracy of data is greater than 99.99%.

2. System capacity index:

2.1 accessible workstations: >10;

2.2 historical data preservation period: more than 5 years;

2.3 the number of temperature measurement terminals accessible: no more than 65,535.

3. System reliability index:

3.1 MTBF of the main station system (MTBF) : >30,000 hours;

3.2 system availability: >99%;

3.3CPU load rate: <40%;

3.4 network load rate: <30%;

3.5 the average number of automatic thermal starts due to accidental failure should be <1 /360 hours.

Five. The System function

1. Temperature collection function.

Through the wireless temperature measuring terminal and the installation of continuous measuring temperature on the cable and cable joint, the bus, the contact,

The running state of cable and cable head is monitored in real time, and the measurement results are uploaded to the monitoring center database via communication network.

The server, through software analysis, can predict the early overheating of the equipment in advance, and realize the early prediction of failure and prevent the disease from occurring.

The function of early warning.

2. Communication function

The data set processor can communicate with the monitoring center through the power grid, or through the GPRS channel.

With the monitoring center, GPRS is provided by professional operators to ensure reliable communication.

3. Data processing function.

The monitoring center receives the individual monitoring-station of field data, through the analysis processing, preservation in the database, and with a wiring diagram, curve and table method is presented to monitor personnel, equipment and automatically detect the presence of thermal or overtemperature, on the basis of intelligent judgment without exception equipment, when there is abnormal situation, automatic with language, sound and light alarm. It is necessary to prevent in advance and ensure the safe and reliable operation of substation equipment.

4. Alarm function

When there is a temperature increase and more than setting the alarm limit, the system will send out alarm in different ways, including network alarm client, SMS, etc., and display the location of the emergency alarm and record the alarm time, timely and accurate guide maintenance and troubleshooting.

Network client alarm module in the received data processing center to send the alarm information, alarm popup Windows on the screen of the client immediately, voice alarm, alarm, screen flashing alarm, including the alarm information, prompt the user to immediately deal with the alarm information. SMS alarm platform to receive the data processing center alarm information, set the alarm plan in advance according to the user, according to the different type of alarm, the alarm device to send staff related to different alarm messages.

5. Browsing function

B/S structure of the monitoring center using the latest design, as long as you have appropriate permissions, on any computer on the LAN access to the data in the database, view real-time temperature and historical data of the monitoring, convenient to browse and manage.

6. User management.

The system has user management function, which can be added or deleted by the system administrator, management authority setting, etc., to ensure the safe operation of the system.

7. Data query function.

The system can query the alarm parameters, alarm recording, sorting and printing of each monitoring point. Check the monitoring parameters, historical data, sorting and printing of each monitoring point; According to the time query, according to the time period query, according to the monitoring station inquiry, according to the alarm query, provides a variety of conditions to inquire.

8. Perfect logging function.

The system can record the user's usage and alarm information. All warning messages can be queried by logging.

The front end of the system adopts the wireless temperature measuring terminal, and the temperature measuring terminal can be conveniently installed on the contact point of the high-voltage charged body to accurately track the temperature change of the hot contact. Using the rf technology to transmit temperature information, the collector and the collection point are realized, which is safe and reliable. This system wireless convergence in the terminal can receive 1024 wireless temperature measurement data of terminals, accurate reports in the operation of all high voltage equipment easy fever parts being measured temperature rise, provide reliable data basis for equipment safe operation, and provide scientific basis for the state of the equipment maintenance; Installed in the monitoring center temperature monitoring software, powerful system database through the man-machine interface to the geographical distribution, junction temperature, operation parameters, forecast alarm information, historical parameters by graphics, tables, such as curve, stick figure, such as forms of visual display, provide the most direct and reliable data basis for policy makers, eliminate hidden dangers and minimize accidents.

Two.System composition

The system consists of wireless temperature measuring terminal, wireless repeater, wireless convergence terminal and background monitoring system.

Three. Technical parameters

1. Frequency range: 433MHz-434.79MHz (no application);

2. Transmission distance: 800m (no obstruction);

3. Output power: +30dbm;

4. Receiving sensitivity: -123dbm;

5. Comply with the requirements of low temperature GB/T2423.1 and high temperature GB/T2423.2, suitable for use in areas with poor weather conditions;

6. Waterproof level: not waterproof, suitable for indoor;

7. Display mode: independent LCD display;

8. Interface mode: RS232, RS485;

9. Interface mode: RJ45 Ethernet interface (optional);

10. Power supply: direct current flow 110V to 240V;

11. Dimensions: 483mm x height 45mm x depth 160mm, height 1U.

Four.Technical indicators1. Accuracy of system data: the accuracy of data is greater than 99.99%.

2. System capacity index:

2.1 accessible workstations: >10;

2.2 historical data preservation period: more than 5 years;

2.3 the number of temperature measurement terminals accessible: no more than 65,535.

3. System reliability index:

3.1 MTBF of the main station system (MTBF) : >30,000 hours;

3.2 system availability: >99%;

3.3CPU load rate: <40%;

3.4 network load rate: <30%;

3.5 the average number of automatic thermal starts due to accidental failure should be <1 /360 hours.

Five. The System function

1. Temperature collection function.

Through the wireless temperature measuring terminal and the installation of continuous measuring temperature on the cable and cable joint, the bus, the contact,

The running state of cable and cable head is monitored in real time, and the measurement results are uploaded to the monitoring center database via communication network.

The server, through software analysis, can predict the early overheating of the equipment in advance, and realize the early prediction of failure and prevent the disease from occurring.

The function of early warning.

2. Communication function

The data set processor can communicate with the monitoring center through the power grid, or through the GPRS channel.

With the monitoring center, GPRS is provided by professional operators to ensure reliable communication.

3. Data processing function.

The monitoring center receives the individual monitoring-station of field data, through the analysis processing, preservation in the database, and with a wiring diagram, curve and table method is presented to monitor personnel, equipment and automatically detect the presence of thermal or overtemperature, on the basis of intelligent judgment without exception equipment, when there is abnormal situation, automatic with language, sound and light alarm. It is necessary to prevent in advance and ensure the safe and reliable operation of substation equipment.

4. Alarm function

When there is a temperature increase and more than setting the alarm limit, the system will send out alarm in different ways, including network alarm client, SMS, etc., and display the location of the emergency alarm and record the alarm time, timely and accurate guide maintenance and troubleshooting.

Network client alarm module in the received data processing center to send the alarm information, alarm popup Windows on the screen of the client immediately, voice alarm, alarm, screen flashing alarm, including the alarm information, prompt the user to immediately deal with the alarm information. SMS alarm platform to receive the data processing center alarm information, set the alarm plan in advance according to the user, according to the different type of alarm, the alarm device to send staff related to different alarm messages.

5. Browsing function

B/S structure of the monitoring center using the latest design, as long as you have appropriate permissions, on any computer on the LAN access to the data in the database, view real-time temperature and historical data of the monitoring, convenient to browse and manage.

6. User management.

The system has user management function, which can be added or deleted by the system administrator, management authority setting, etc., to ensure the safe operation of the system.

7. Data query function.

The system can query the alarm parameters, alarm recording, sorting and printing of each monitoring point. Check the monitoring parameters, historical data, sorting and printing of each monitoring point; According to the time query, according to the time period query, according to the monitoring station inquiry, according to the alarm query, provides a variety of conditions to inquire.

8. Perfect logging function.

The system can record the user's usage and alarm information. All warning messages can be queried by logging.