One.Overview

The intelligent control cabinet is suitable for the strong oil air cooling system of transformer cooling system. The intelligent controller based on the importance of using occasions, in order to "reliability" for the first design principle, uses the international well-known brand - schneider electric components, intelligent part adopts the Siemens 200 programmable controller. This intelligent control cabinet of the shell is made of high quality stainless steel structure, the top has a vent hole, and is equipped with strong axial flow fan, the lower part has the ventilation filter, protection grade is IP56, suitable for outdoor use for years. According to the running time of each cooler, the intelligent control cabinet automatically sets the work, auxiliary and standby mode of each cooler, and the coolers automatically rotate each week (168 hours). At the same time, this cabinet also provides local manual control mode and remote manual control. When using remote manual control mode, DCS system can directly start and stop each cooler. This intelligent control cabinet fully plays the role of intelligence, provides good fault display and analysis judgment function, user can conveniently and quickly eliminate the fault.

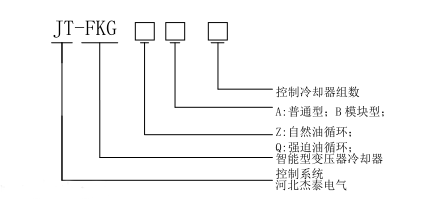

Two.Model specification

Three.Functional description

1. The input and exit of this cabinet.

When the transformer is out of operation, the cooling system controlled by the cabinet is withdrawn. When the transformer is put into operation, the cooling system controlled by the cabinet is in operation.

2. The mutual backup function of power dual power supply circuit.

Dual power redundant power supply, when any power supply failure, can realize the automatic input of the other power source. Dual power supply into the terminal voltage monitoring relays - KX1, - KX2, when any power failure occurs, all the way the other power supply will automatically put all the way, and to provide local display and remote signal of power failure.

3. Automatic sorting function of cooler.

The control cabinet to provide cooling system of automatic sorting, according to the length of each cooler running time set each cooler, auxiliary and standby state for work, every time sequence will reset the cooling system working condition.

4. Manual and DCS functions of DCS cooler.

When SAM3 is placed in remote control mode, dcs1-n can directly start and stop the cooler. When SAM3 is placed in the "local" control mode, the control cabinet accepts local control.

5. Status display and fault monitoring function.

1 power failure monitoring.

Power dual power supply: when the power dual power supply any fault, send out the local light signal alarm light, and distant signal.

Dc power supply: when control DC110V fault, dc fault light is on.

2 transformer trip signal monitoring.

The high, medium and low pressure switch of the transformer is closed and the CPU receives this signal to stop the program.

3 the signal of the transformer is monitored.

Oil level temperature signal: when - BT1 low temperature contact closure, auxiliary Ⅰ cooler in operation, the signal disappeared after running continuously for 10 minutes; When high temperature - BT1 contact closure, auxiliary Ⅰ and auxiliary Ⅱ cooler into, signal disappears after running continuously for 10 minutes.

Load current signal: 0.6 I N the load current signal, in the way of auxiliary Ⅰ cooler, load current 0.8 I N signal in the auxiliary Ⅱ way cooler. Run for 10 minutes after the signal is gone.

4 Full stop transformer trip signal of the cooler.

When the power double power supply fails or the cooler is fully stopped, and the -bt1 temperature does not exceed the high temperature alarm signal, the delay time is 60 minutes, and the main variable tripping signal is issued; When the -bt1 sends out high temperature signal and the power double power supply fails or the cooler is fully stopped, the delay time is 20 minutes, and the main variable tripping signal is issued.

5 heating, ventilation and lighting function.

In the control cabinet installed heating, moisture and ventilation, by temperature and humidity controller in the real-time monitoring the change of running environment, automatic control of heat, moisture and ventilation, to ensure that the electrical components in a suitable environment reliable operation, set up in the control cabinet lighting, when the cupboard door open or close, lights light up or put out automatically, convenient maintenance at night.